- Home

- Industrial Epoxy Flooring

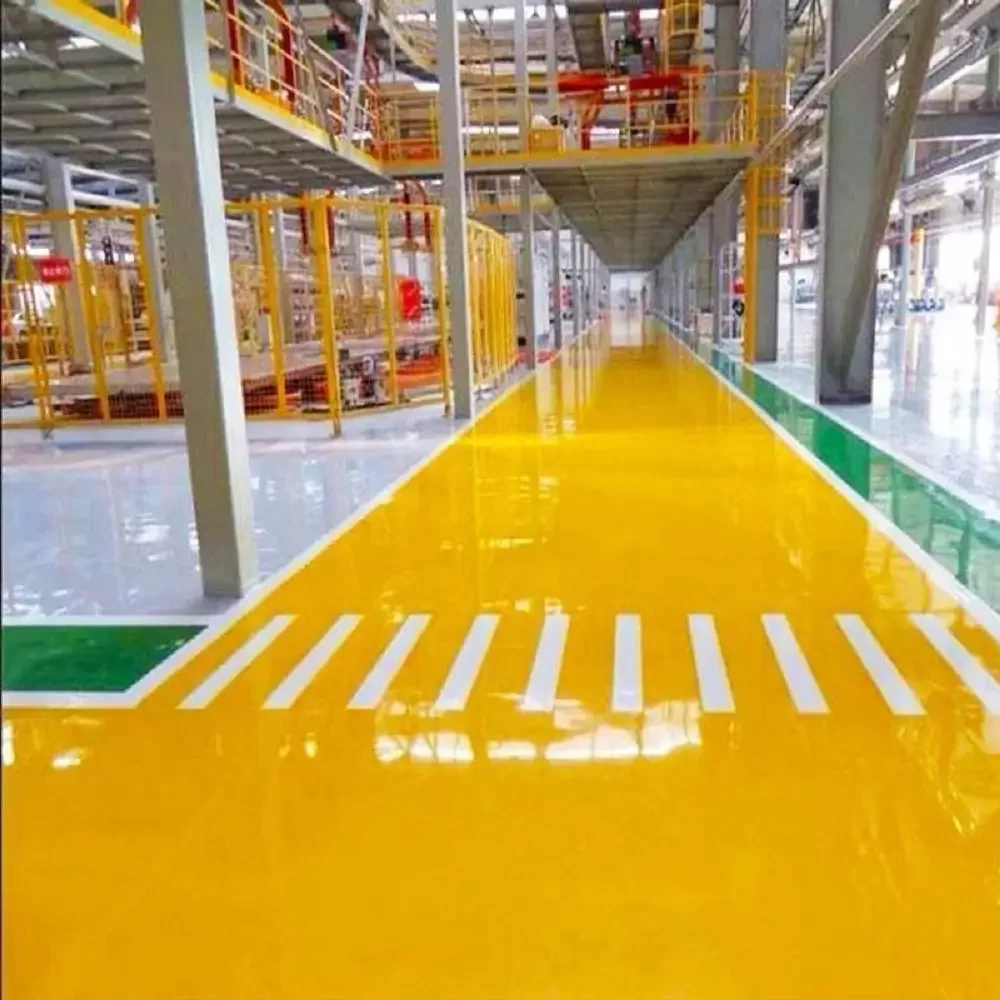

Best Industrial Epoxy Flooring Service Provider in Dubai and Abu Dhabi

When it comes to Industrial Epoxy Flooring Dubai and Abu Dhabi, we stand out as your go-to experts. Our best industrial epoxy floor coating gives you surfaces that last long stay tough, and remain smooth, ready to handle whatever your industrial setting throws at them. If you need industrial epoxy floor paint or want to find skilled industrial epoxy floor coating contractors, we’ve got you covered. Give us a call for top-notch flooring solutions, and we’ll set up a meeting to figure out what you need. Get your installation on the calendar today and see for yourself what quality service looks like. Choose us for the cream of the crop in this field.

Looking for the Best Industrial Epoxy Flooring Shop/Store in Dubai and Abu Dhabi for Commercial Projects?

Our Industrial Epoxy Flooring Abu Dhabi and Dubai offer the best option for your business projects. Our team of skilled professionals provides high-quality industrial epoxy flooring dubai that stand the test of time and suit your company’s requirements. If you need industrial epoxy floor paint or are looking for dependable industrial epoxy floor coating contractors, we have the know-how to deliver great outcomes. Stop by our locations in Dubai and Abu Dhabi to check out the top flooring options and set up a meeting with our capable team right away!

On-Demand Features of Our Industrial Epoxy Flooring

Our Industrial Epoxy Flooring Dubai has a bunch of top-notch features you can ask for to keep things safe and high-quality:

- Antibacterial: Keeps your space clean and germ-free.

- Fire Rated/Fire Coated/Antifire: Stands up to fire well making things safer.

- Eco-Friendly: Uses materials that are good for the planet.

- Waterproof: Stops water from causing damage great for wet areas.

- Free Interior Design Service: You get help from experts to make your industrial space look just right.

Unlock 30% Discount on Selected Range – Limited Time Offer!

Don’t let our special 30% off deal on select Industrial Epoxy Flooring Abu Dhabi products pass you by! Now’s your shot to upgrade your floors with industry-leading options at prices you can’t beat. Grab this time-sensitive deal and get top-quality epoxy floor coatings with amazing savings and markdowns. If you’re thinking about a commercial update or a full industrial redo, it’s time to make your move. Schedule your install today and lock in your savings before they’re gone! Quick, time’s running out – don’t miss this chance!

Types of Industrial Epoxy Flooring We Provide

- Self-Leveling Epoxy Flooring: This flooring suits areas that need a smooth unbroken surface. It evens out on its own to create a flawless look offering toughness and the ability to resist wear.

- Gravel Epoxy Flooring: This type works well in busy areas. It blends good looks with strength standing up to heavy weights and impacts while keeping a rough appearance.

- Anti-Slip Epoxy Flooring: Safety is the main focus of this flooring. It has a rough surface to stop slips and falls making it a good fit for industrial settings with big machines.

- Conductive Epoxy Flooring: This flooring helps to get rid of static charges. It’s great for places that use delicate equipment or electrical parts.

Benefits of Industrial Epoxy Flooring We Provide

- Durability: Our Industrial Epoxy Flooring lasts a long time. It stands up to heavy use and keeps working well in busy areas.

- Cost-Effective: Epoxy flooring costs less to put in and take care of. You’ll spend less money over time because you won’t need to fix or replace it as often.

- Easy Maintenance: Our epoxy flooring has a smooth top that doesn’t let stuff soak in. This makes it simple to clean and keep looking good.

- Enhanced Safety: Our epoxy flooring helps prevent slips. This makes industrial spaces safer and cuts down on accidents and injuries.

Your Trusted Industrial Epoxy Flooring Service Provider Across All Emirates of UAE

We’re the top Industrial Epoxy Flooring Abu Dhabi company in the UAE. We work in all Emirates, including Dubai, Abu Dhabi, Sharjah, Ajman, Ras Al Khaimah, Fujairah, Umm Al Quwain, and Al Ain (Abu Dhabi). Our team knows how to make epoxy floors that last, work well, and don’t break the bank. We fit our work to what your industry needs. No matter if you’re in a busy city or somewhere out of the way, we’ll show up on time and do a good job. Get in touch with us now to make your industrial space better with the best epoxy flooring in the UAE, which you can get in any Emirate!

Our Gallery

Why Choose Us for Industrial Epoxy Flooring?

- Expert Team: Pros with loads of know-how in delivering first-rate industrial epoxy flooring abu dhabi answers.

- Durable Solutions: We offer epoxy coatings that last and hold up in busy and tough settings.

- Tailored Services: Custom floor options made to fit your exact industrial needs, from self-leveling to non-slip coatings.

- Premium Materials: We use top-notch stuff for better performance and a longer life.

- Competitive Pricing: Good rates without cutting corners on quality or service.

- Fast Turnaround: Quick and smooth setup cutting down on lost time for your business.

- Top-Notch Customer Service: Devoted help all through your project.

Meet Our Expert Industrial Epoxy Flooring Team – Our Team Works 24/7!!

Our Industrial Epoxy Flooring Abu Dhabi team stands at the core of our achievements ready 24/7 to offer the best industrial epoxy floor coating answers. Our specialists bring years of know-how to the table focusing on industrial epoxy floor paint and serving as trustworthy industrial epoxy floor coating contractors to guarantee top-notch outcomes for each job. We get what your business needs so we provide on-demand services that fit your timetable and requirements. No matter if you need a tricky setup or upkeep, our crew stands ready to set up a fix anytime bringing you unbeatable quality and care.

FAQs about Hospital Carpet

Ans: Industrial Epoxy Flooring is a durable, high-performance flooring solution designed for heavy-duty environments. It’s made of epoxy resin and hardeners that create a strong, long-lasting surface that resists wear, chemicals, and impacts.

Ans: The key benefits include durability, chemical resistance, easy maintenance, cost-effectiveness, and safety (with options like slip-resistant surfaces). It also provides a smooth, seamless finish that enhances the aesthetic and functionality of industrial spaces.

Ans: With proper maintenance, Industrial Epoxy Flooring can last 10-20 years, depending on the type of flooring, the environment, and the level of foot or vehicle traffic.

Ans: Yes, Industrial Epoxy Flooring is versatile and can be used in a variety of industries such as manufacturing, warehouses, food processing, pharmaceuticals, automotive, and more.

Ans: Yes, we offer customized solutions, including various colors, textures, and finishes, to match your specific requirements, whether it’s for a factory, warehouse, or office space.

Ans: Maintenance is easy! Simply sweep or mop the surface regularly. For more stubborn stains, you can use a mild detergent and a soft brush to clean the surface.